“This bike started life as the “Meat Grinder” chopper Sportster we had built about 5 years ago, with a hardtail, matching 19” wheels, weird bars and a springer solo seat. We needed the engine from that bike to power our land speed racer Sportster, so the bike was stripped and sat neglected for a while.”

“We decided that suspension was a good thing, so we located a swing arm, a 16” rear cast wheel and some shocks. From there we started tracking down all the parts we would need to make it a runner. We fit a front disc to complement the rear, a set of drag bars for just about the simplest riding position you can find and of course a new engine since the original was long gone. The engine we found was a basketcase out of a ’78 so we dug out what we had around the workshop and ordered everything we needed to get it running. The budget was initially a concern, but we were soon way past the point of a simple ‘make it run’ build.”

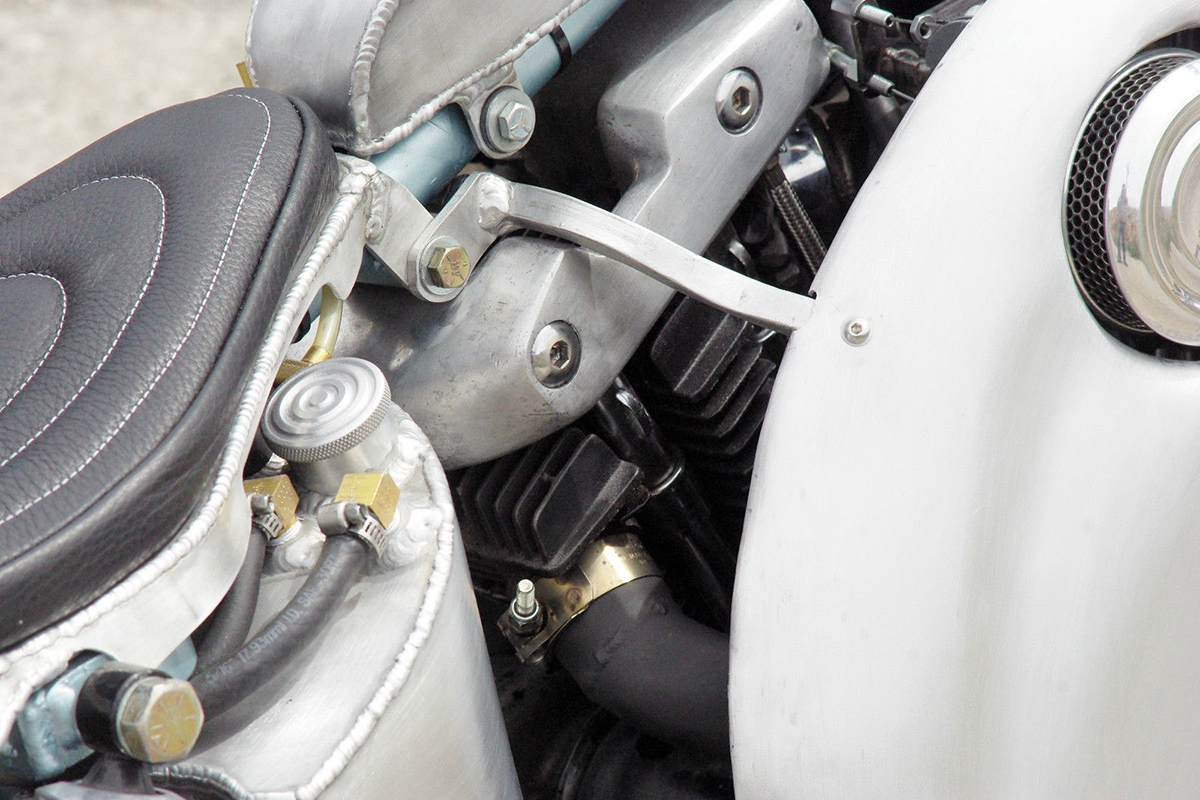

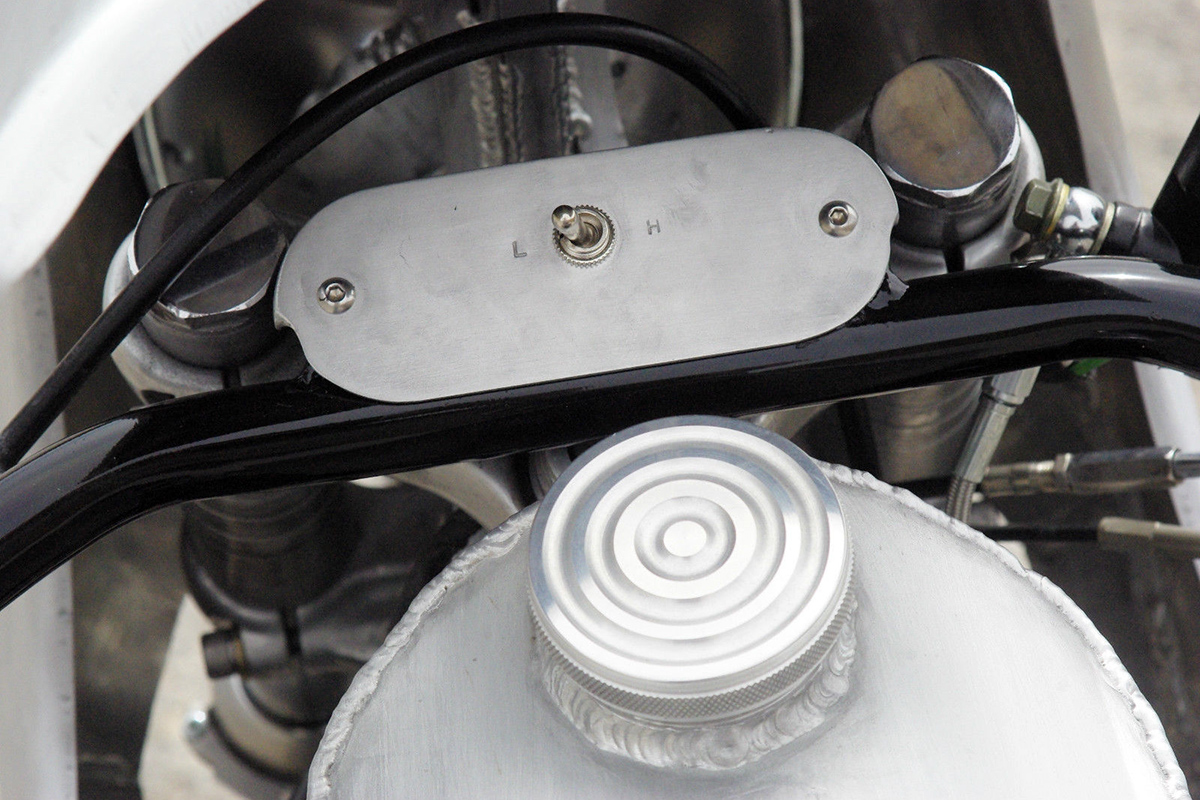

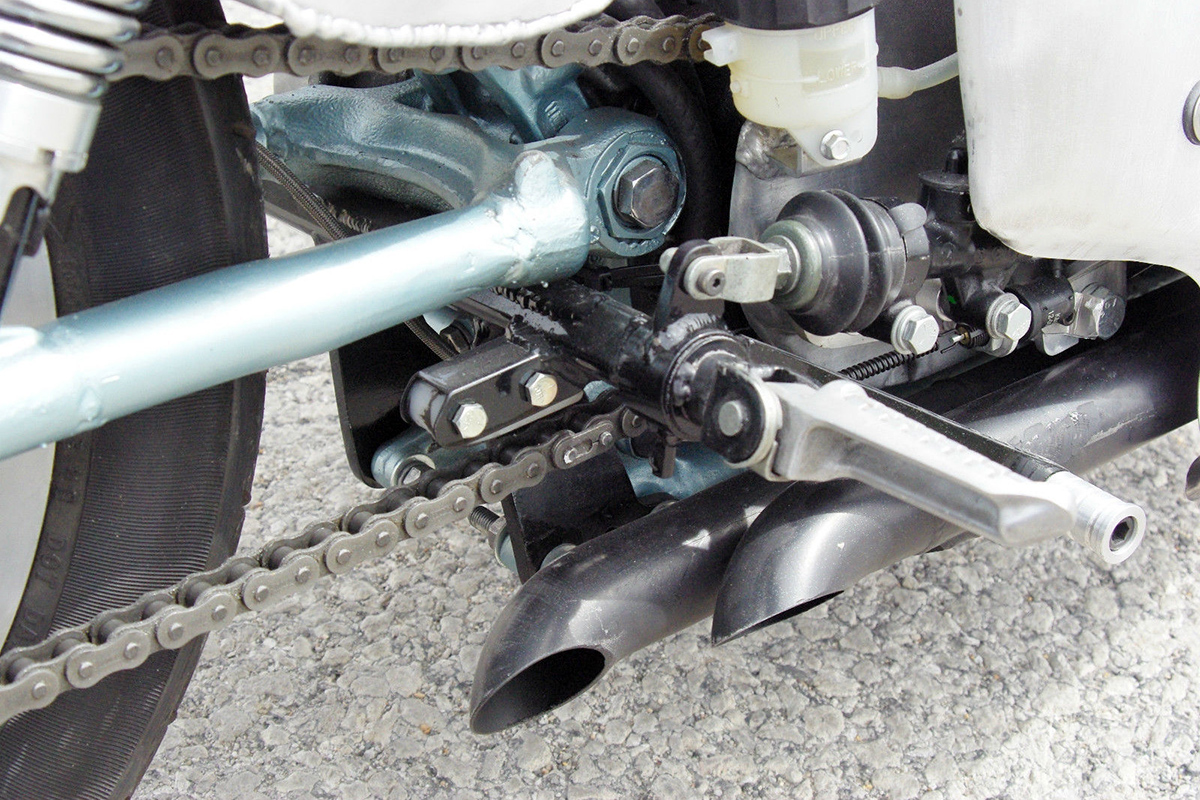

“During the engine rebuild the bodywork was coming along nicely. We built a compact, sleek aluminium setup. The fuel tank, oil bag and solo tail section were all made from .060” 5052 aluminium, not the easiest to form, but it is very stiff and highly corrosion resistant. Instead of mimicking the polished look of the land speed racer we went with a raw, brushed finish. Amidst all of this, there were several other components being completed. The exhaust was welded from various sections of bends, the rearsets were custom made to mount off the original frame exhaust mounts, and a GP style shifter (1 up and 3 down now) was bolted in place.”

“Once the body and the engine were complete we fired it up and commenced the break in. Well, after about 5 minutes of run time the engine seized! It wasn’t the result we were hoping for. We tore it completely down again, replaced the damaged pieces and realised we were missing a bearing spacer on the left side of the crank. We located and fit that, did some transmission work, and reassembled. Bingo! It ran great. The Cycle Electric Generator, Andrews PB+ cams, and Mikuni HS40 flat slide carb all worked great. The bike wasn’t actually legal to ride yet but we got some short runs in and then had another bright idea. To build a full fairing for it.”

“The one piece fairing is made from the same .060” 5052 aluminium, but this time we gas welded it together. Gas welding alloy compared to TIG has the advantage of better penetration and it’s more ductile so you can get a better finish. It started as 13 pieces and finished as one smoothed unit. It is all one piece and can be removed completely. The mounts are all bolt on, and this is basically two bikes in one, a fully faired cafe racer or a naked bike.”

“By this time we had worked most of the bugs out of the engine- there’s a bit of smoke on hard decelerate, it runs rich at our elevation of 4700 feet and there is a stutter on full throttle in 1st and 2nd gears. Unfortunately, we have taken the bike as far as we can on our budget and limited resources and we’ve got to move on to the next one. It really is a diamond in the rough and with a bit of extra finishing could be great!”