After spying the Yamaha XJR400 cafe racer on their website we contacted C-Racer crew member Antonis Kapetanios who was kind enough to walk us through the build…

“The C-Racer #2 is our follow up build to last year’s Suzuki GX250 ‘Sugar Kane’. This new build was undertaken to demonstrate how our C-RACER custom parts can be fitted by people who share the same passion for customizing bikes as we do. The #2 project started out life as a ’93 Yamaha XJR400 that we purchased in fairly good condition for only 800 euro. As a team, we decided that our goal was to build another “pure” café racer that was suitable for everyday use.”

“To begin with we opted to use the SCR2.1 seat with the 50mm stop light from our own product catalogue. The original subframe was completely removed and replaced with a new one that followed the lines of the seat. We then took all the electrical components, including the battery and hid them in the cowl and beneath the seat base. In order to realign the tank to match the bone line of the frame, we raised its mounting points by 4cm. We also cut 2cm off the tank’s rear end so that it would match the seat perfectly, creating a smooth curve and giving it the appearance of a monocoque body.”

“The marriage of Café Racer styling with a bike made for everyday use can be problematic. After heavy consideration and numerous tests, we came up with the idea of repositioning the handlebar clamps horizontally between the fork tubes and attached a set of totally different handlebars. We then constructed a CNC aluminium top triple tree to hold the aftermarket speedometer. Attached to the lower triple tree is a metal plate that provides 4 height adjustment positions for the handlebars, giving the rider the ability to position them as aggressively or relaxed as they like. The handlebars clamps mount directly to the plate and hold a set Renthal tracker bars in place, and it’s all tucked away behind out MCR1 fairing. We were all amazed by the final outcome of this setup. It has the appearance of a set of clip-on bars, yet it’s a much more comfortable riding position. It also gives the front end of the bike a much cleaner appearance.”

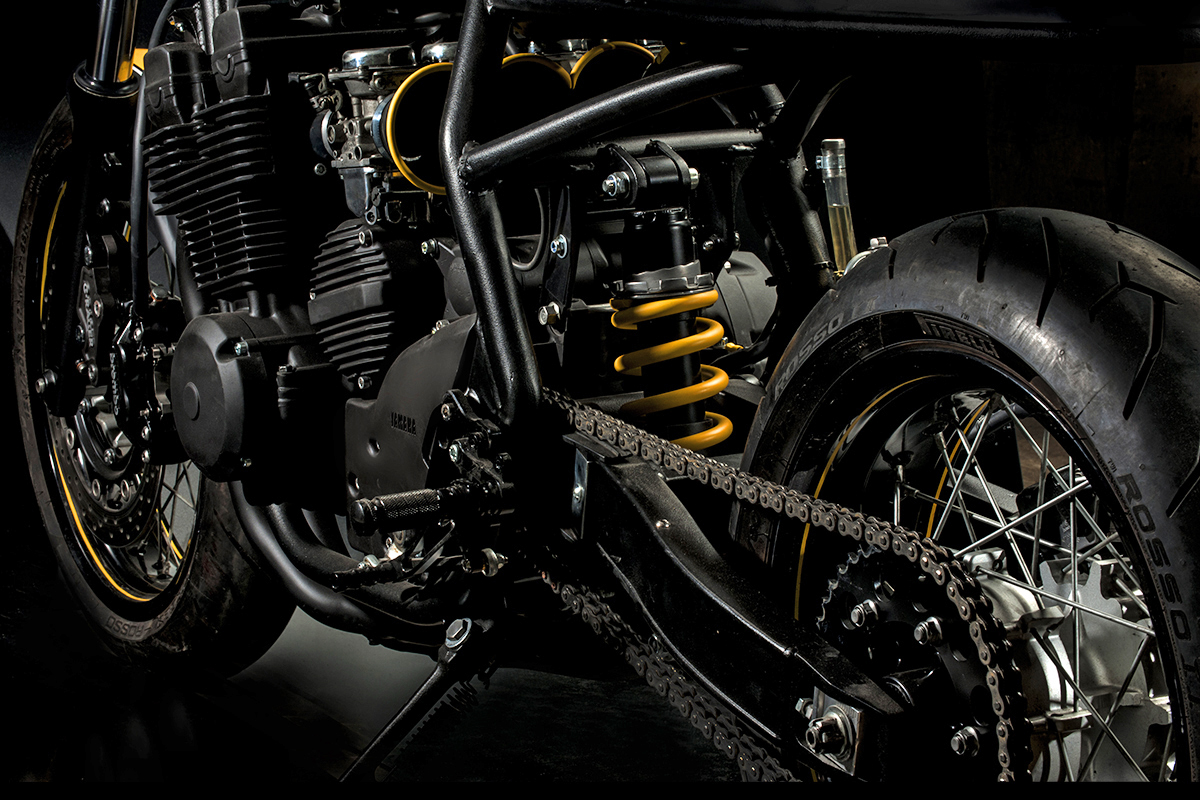

“The twin rear shocks have been with a monoshock configuration by reinforcing both the swing arm and the frame. The linkage system we used to put it all together is from a KTM LC4 and the monoshock itself was borrowed from a Yamaha FZ600. Along with that we had to build new longer brackets to achieve the desirable height and performance characteristics we were after.

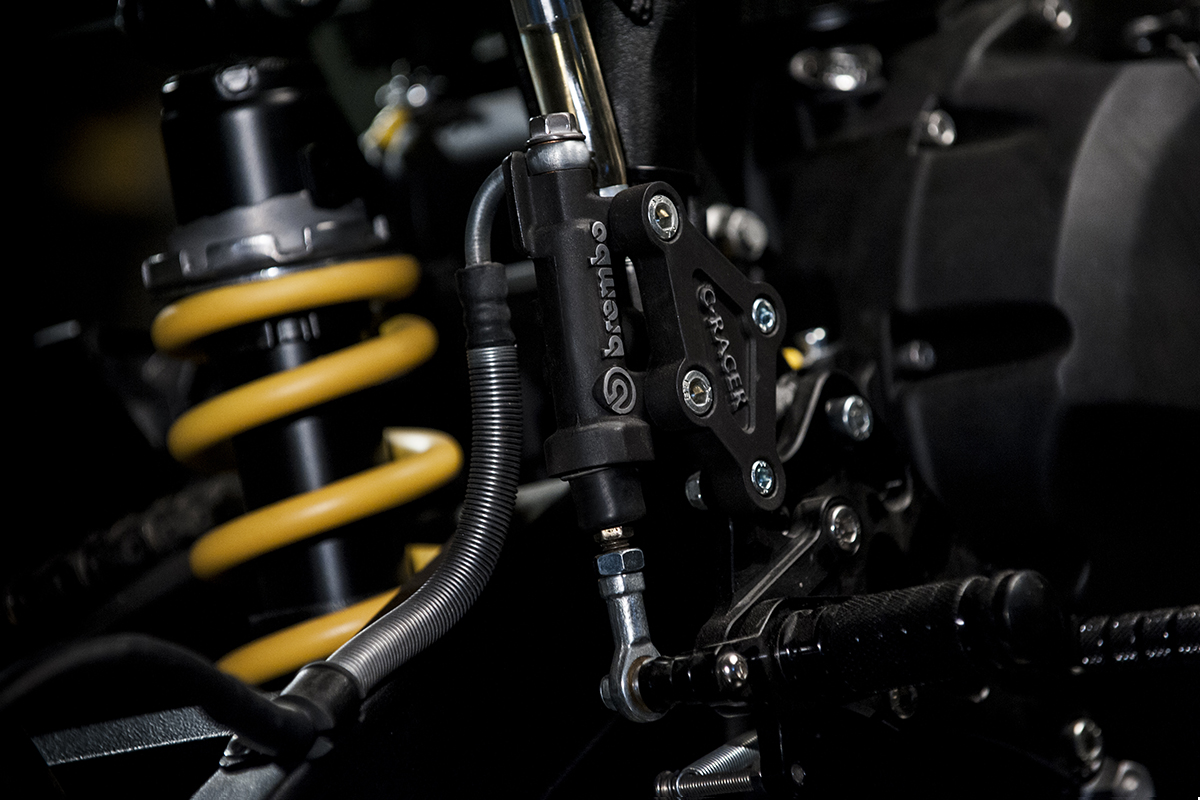

One of the major decisions we had to make during the build were the type of wheels and brakes to install, since we didn’t want to keep the originals. We settled with a pair of XT660 excel rims and their matching Brembo brakes. Both the fork tubes and swingarm were modified to fit the new wheels, a process that included machining spacers to centre the wheels correctly. Using the CNC again we then built base plates for the brakes and brackets for our UFF3L fender.”

“The stock air box was replaced with 3D printed velocity stacks and the stock oil cooler with a smaller, less intrusive one. We also installed a new ignition key and horn beneath the front end of the fuel tank which is almost completely hidden from sight. We retained the stock exhaust headers, but created a custom a muffler by cutting up an Emgo bell-end megaphone, adding a trick grill to close up its wide mouth.”

“Finally, for the paint job, we wanted to use our C-RACER colours. We sandblasted all the parts of the bike, including the frame and powdercoated them with matte black. We completely dismantled and rebuilt the engine, also painting it black, and laid a saint finish yellow stripe with a white pin from the front fender to the tip of the tail. We then added a yellow perspex windshield to our fairing to complete the look.

The Yamaha XJR400 proved to be a bigger challenge than expected; there are plenty of different builds of this bike out there, so we challenged ourselves to make a difference. We hope we achieved it.” says Antonis.

While some will be quick to point out that “bolt on” and “custom” are 2 very different things, I think it’s important to realise that at the end of the day it’s about achieving your goal. After all, it’s your bike you’re messing with, not theirs. Let us know where you stand on this topic by contributing to the comments section below.

For a closer look at the C-Racer product catalog hit the link below.

Let’s face it. While the idea of building your own custom motorcycle, using parts you fabricated with your own two hands might sound like something we’d all like to do, the reality is that it’s a task not everyone is capable of. In fact it’s likely there are very few builders in your home town that go to the extent of hand forming bodywork or bending up their own exhausts. Meanwhile the rest of us rely on aftermarket suppliers to provide us with bolt on solutions for the parts we simply don’t have the skills or the inclination to produce ourselves. One such aftermarket company we’ve been watching for some time is the Greek workshop C-Racer. With a rapidly growing catalogue and distributors popping up around the globe we thought we’d touch base with them to talk about their latest project.