“We have been so consumed with customer work that we haven’t been able to build a shop bike since we open our doors to the public a year and a half ago,” says Trever. “This bike started as a 40% complete build. The owner wanted to change up the oil tank, make a proper seat and get the carbs put back together. Once the metal work was done and the frame painted things quickly escalated, and it soon turned into a full nut and bolt build.”

The donor for the project was picked up in the backwoods of Alabama after sealing the deal on eBay for $800. Unfortunately, it wasn’t much of a runner with cracked intake boots, dodgy old lines and a couple of handfuls of bees encrusting the petcock. The bike had also already seen some custom work that was all pretty rough. So once it was decided that the bike should undergo a full rebuild Trever worked with the owner on a concept.

“From the beginning, the bike was meant to be a fun, reliable daily rider. Marty (the owner) is a real estate agent, so he needed something to dart around town on and check out potential listings.” Trevor recalls. “He wanted the bike to look custom yet subtle at the same time. This fit our building style perfectly. There are provisions for riding two up with comfort and the rear shocks are adjustable to accommodate the added weight. As much as we like to make beautiful bikes, we have a heavy emphasis on building usable and comfortable bikes that you can put miles on with ease.”

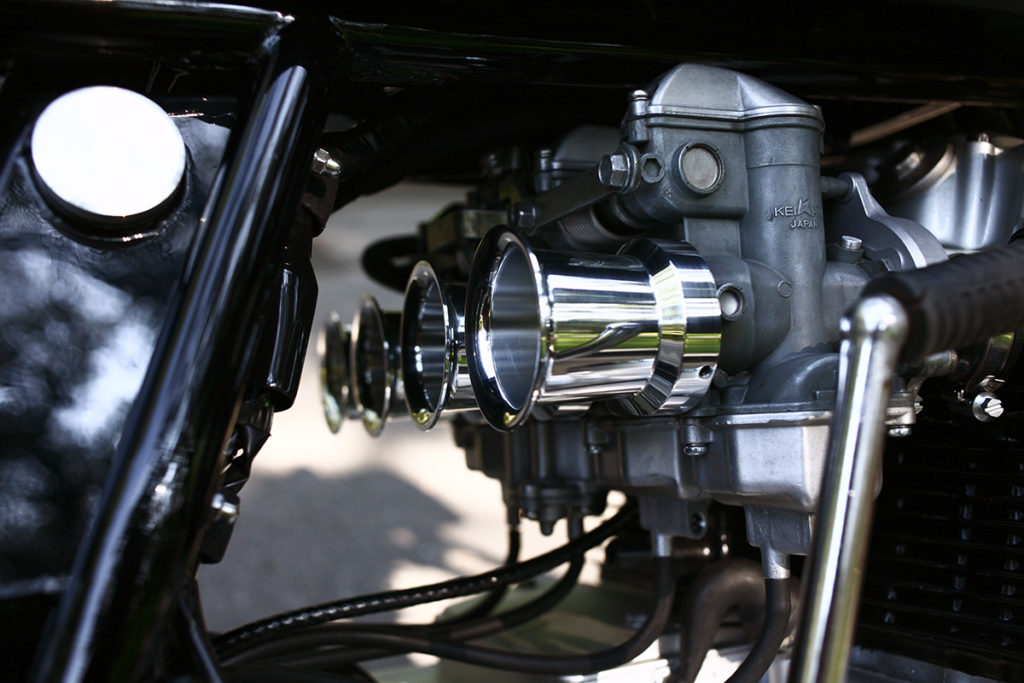

To clean up the rear end the bike had a Cognito Moto rear hoop and oil tank tig welded on. Scale the shaped the seat, using DZUS fasteners from a Ducati 999R to hold it in place. The special fasteners allow quick access to the battery within seconds and doesn’t require the use of any tools. The frame was de-tabbed and smoothed right down to the swingers for a super clean finish. A Balistic battery was mounted in a custom box beneath the seat and secured using the same leather that covers the new seat. The wiring harness is a one-off and Moto Gadget supplied the bar end turn signals and grips. Most of the other aftermarket parts Marty wanted were sourced through Dime City Cycles including the velocity stacks. “We smoothed out the fins on the header clamps and had them chromed by Speed Sport Chrome,” says Trever. “Every piece including the motor mounts and the ends of the swing arm had their rough casting marks ground down and smoothed out before it was all covered in PPG paint.”

“Marty took it upon himself to have a custom gas cap cast by CraftyB with ‘SCALES’ cast into it. We ended up cutting out the original gas door and making a fill piece which was tig brazed in with bronze. The indents for the logos on the side of the tank were filled with bronze as well. We raised the rear mounting point of the tank 1 inch which gave it a more aggressive stance on the frame and allowed us to tuck the seat under the tank instead of butting the seat up against it like many do. I mixed the grey color by hand and ended up with what we call a ‘Cosmic Grey’. The oil and gas tank received a lot of block sanding time to get the mirror like finish. All the line work was done by hand.”

“We also fabricated the mounts for the tach and choke which kept them flush with the Cognito Moto upper triple clamp. The exhaust is a MAC 4-into-1 with the slip-on joint removed and muffler rotated to kick up. We then ceramic coated the whole unit to keep temps down in Houston’s heat.

The trickiest part of the build was fitting all the electronics under the tank and making the wiring look clean. No rat’s nest to be found here when you peek under the tank. The bike starts first kick every time and has a healthy pull. Confidence in her reliability has been restored!”