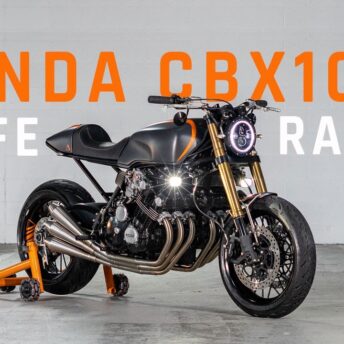

Back in 2012, I was contacted by Vaughan in Sydney who had just finished hammering out the bodywork on his RAW Honda CBX1000 Cafe Racer. Since then he’s been refining and tuning the bike and planning the final touches to get finish this beast of a project off. When I first saw it back then I was blown away by the work that had gone into the build and the unique design he had created and again I’m so damn impressed by the finished product that I had to share with you all again. I got in touch with Vaughan and he was kind enough to give us a full update on what he’s been doing with the bike…

“For many years I had a great deal of difficulty finding metal shaping equipment small enough to fabricate the tight radius and compound curves found on motorcycle parts. So immediately after completing RAW in bare metal Georgio and I decided to design and make a high-quality bench mounted cast iron, Australian made wheeling machine. We started in Oct/Nov 2012 and with the help of a skilled pattern maker and master machinist we had a prototype by approximately May 2013.”

“After completing approximately 1000km of testing and problem solving on the CBX we began the strip down immediately after the Throttle Roll event in May 2013. There were a number of issues to deal with and some things I thought would really improve the bike. Julian began the process by stripping, inspecting and measuring all the components. With only 9000US miles on the bike, it was totally unmolested internally, the biggest problem was the cylinders were glazed and as a result, kept fouling plugs and burning through oil. The plan was progressing well and again the deadline was the Ton Up boys Sydney Rockers Ride (October 13, 2013), that’s our annual unveiling event for new concepts and completed bikes.”

“Julian meticulously replaced all the rings, seals and bearings in the engine, simply because they were rock hard and after being disturbed would leak. The cylinder head was vapour blasted and rebuilt as a precaution and the cylinders honed. The engine parts have had quite a lot of time put into finishing them. We used traditional Cafe Racer and Honda racing colours and whatever coatings (ceramic, paint, plating, polishing, vapour blasting) would produce the best result.”

“I hadn’t been happy with any of the headlight brackets or instrument mounts available so I decided to make new parts that were more in keeping with the overall design and intent of the bike. Looking closely at it there are many small details that I’ve done to the bike to improve the quality of the components and to add some of my own style of bling. For example, the original seat cracked the alloy base (my design fault) so iI redesigned the seat base and padding. When I took the seat for trimming (Hytone motor trimmer in Sydney) I asked them if they saw the bike parked in the street and were looking at another trimmers work I would like them to think that its a quality piece of craftsmanship. That’s my underlying philosophy for anything that is worthy of anybody’s dedicated time and effort. As JohnBritten said “you can spend the same amount of time making something ugly”.”

“The frame was re-blasted and powder coated white, also all the little brackets and parts that had been fabricated had the finishing touches done to them. I was really impressed with the nickel plating from swift electroplaters (its a surface plating developed prior to chrome 1920-30’s used on vintage cars). The paintwork of the components (Thanks to Garry Hall) and the polishing, powder/ceramic coating, vapour blasting etc was all coming along very well. I was leaving the hardest parts till last because i was getting bogged down in the small details.”

“Painting the bodywork really stressed and stretched me because I wanted a 2K clear that would be a high gloss hard surface finish and stick to the polished/painted alloy bodywork. The bike was taking up all my spare and I had a big step backwards when the clear 2K that was supposedly made for the job promptly peeled off as it was being polished! That costs me 2 weeks of work, money and many favours were begged in my panic (many thanks for your help Francisco Granero). A huge thanks to Brad Franklin from BNT panel shop in Artarmon, he saved my arse using a combination of products to achieve surface adhesion. With 2 weeks to go, we had to complete the engine assembly and all we had was a white painted frame. We dedicated ourselves to the task and took sickies (Shh!), the bike was test ridden one day before the event. It performed like clockwork and was an excellent result after all our hard work.”

“I forgot to mention that during this entire process with the Honda we were building Julian Lopez’s prototype KTM Cafe Racer. This bike will hopefully be finished for the Rocker Ride 2014 and Georgio’s concept BMW we hope will be up and running in bare metal. Ultimately in the future, we would love to design/build factory inspired prototype bikes with short production runs and maybe teach others how to do the same using our equipment.”

So there you have it. After our first glance, I was left thinking all that was left was a lick of paint, but as they say, if you’re going to do something you may as well do it right!

Love iy.

It is Awsome.

Great workmanship.

Eddi